- Pigment[7]

- Plastic Film[5]

- Other Safety Products[9]

- Plastic Sheets[6]

- Stair Parts[2]

- Other Security & Protection Products[1]

- Safes[1]

- Plastic Masterbatches[1]

- Plastic Crafts[3]

- Tiles[1]

- Glass Crafts[1]

- Contact Person : Mr. Mike Xu

- Company Name : Lanxi Minhui Photoluminescent Co., Ltd.

- Tel : 0086-579-88948789

- Fax : 0086-579-88948948

- Address : Zhejiang,Lanxi,18 NO,Yuezhong Street

- Country/Region : China

- Zip : 321100

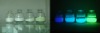

phosphorescent pigment

MHG Type is the most common use photoluminescent powder. It has the feature of high brightness and long afterglow.The light wavelength is 520um.It is widely applied in variety of transparent mediums to make them glow.

| Model | Size (um) | Afterglow Intensitymcd/ | GlowingColor | Appearance Color | ||||

| 1min | 5 min | 30min | 60 min | glow time | ||||

| MHG-4B | 65~75 | 3840 | 1200 | 240 | 115 | >12hr | Yellow-green | Yellow-green |

| MHG-4C | 45~55 | 3200 | 990 | 170 | 75 | |||

| MHG-4D | 25~35 | 2300 | 650 | 120 | 55 | |||

| MHG-4E | 5~15 | 1130 | 320 | 55 | 28 | |||

| MHG-2C | 55~75 | 2750 | 820 | 140 | 65 | |||

| MHG-2D | 15~45 | 1610 | 450 | 75 | 35 | |||

| MHG-1D | 15~65 | 1387 | 380 | 60 | 26 | |||

Brightness testing Situation: D65 standard light source, illumination 1000LX,excitation 10min.

Special granularity of photoluminescent pigment can be processed based on customers' requirement.Instruction 1.Except MH-W, most of MinhuiTM light materials are slightly soluble and decompose in acid. So they can not be applied in water-soluble system and acid system. 2.The brightness is usually better when the granularity of photoluminescence powder is bigger. We suggest that you should choose light material with right granularity according to your manufacture technics. For example: MHG-4B is suitable for painting and roller coating the road surface with good light effect, but rough surface; MHG-4C is suitable for painting, roller coating, silk-screen (80 mesh) printing and injection molding; MHG-4D is suitable for painting, roller coating, silk-screen printing (160 mesh) and injection molding. 3.The light material is dense, please mix uniformly when use. 4.It should be stored in ventilated and dry environment. The opened material should be sealed. 5.Metal material affects the performance of light, please avoid to touch the metal material. Packaging,Transportation and Reserve Packaging: The inner packing is waterproof plastic bag (1kg/b); the outer packing is plastic pail (25kg/pail). We also could pack in other modes to meet clients' demands. Transportation: Prevent colliding and extruding, keep away off sun and rain.Reserve: It should be stored in ventilated and dry environment.

phosphorescent pigment